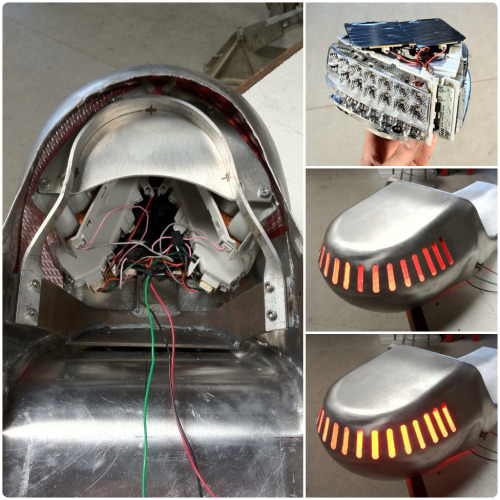

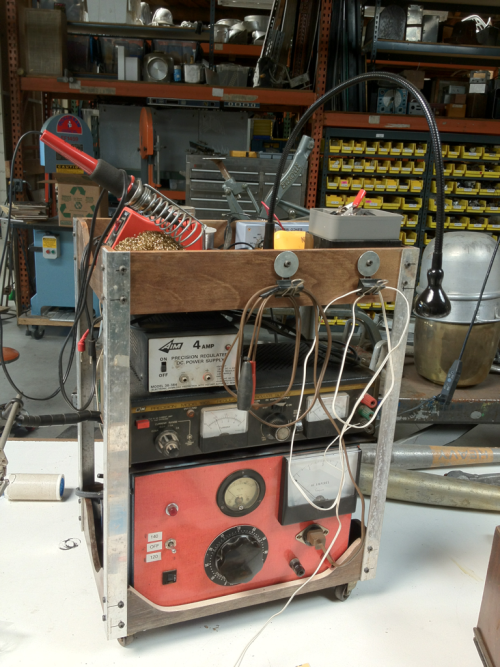

So, I haven’t posted anything in a while but I’ve had a good reason. The image here may look a lot like a motorcycle, but it isn’t. Well, it is, but it’s a lot more. It’s a first step towards breaking my total dependence on found objects for source material.

Waaaay back when I first started making things in metal I went with found things because I didn’t have the skills to make the shapes that I wanted to. This project represents my first attempt at building forms from sheet stock. It’s a steep learning curve, but I’m beginning to see the way it works. I figure that by the time I build all the body work on this motorcycle (the tank is coming along nicely) I’ll have developed the skills to apply this technique to sculptures. I’ve had a lot of false starts, and a lot of material has wound up in the scrap bin, but stay tuned, things are starting to flow now.